Polished Wired Glass

Wired glass is produced by carefully embedding wire mesh or metal wires

into glass.

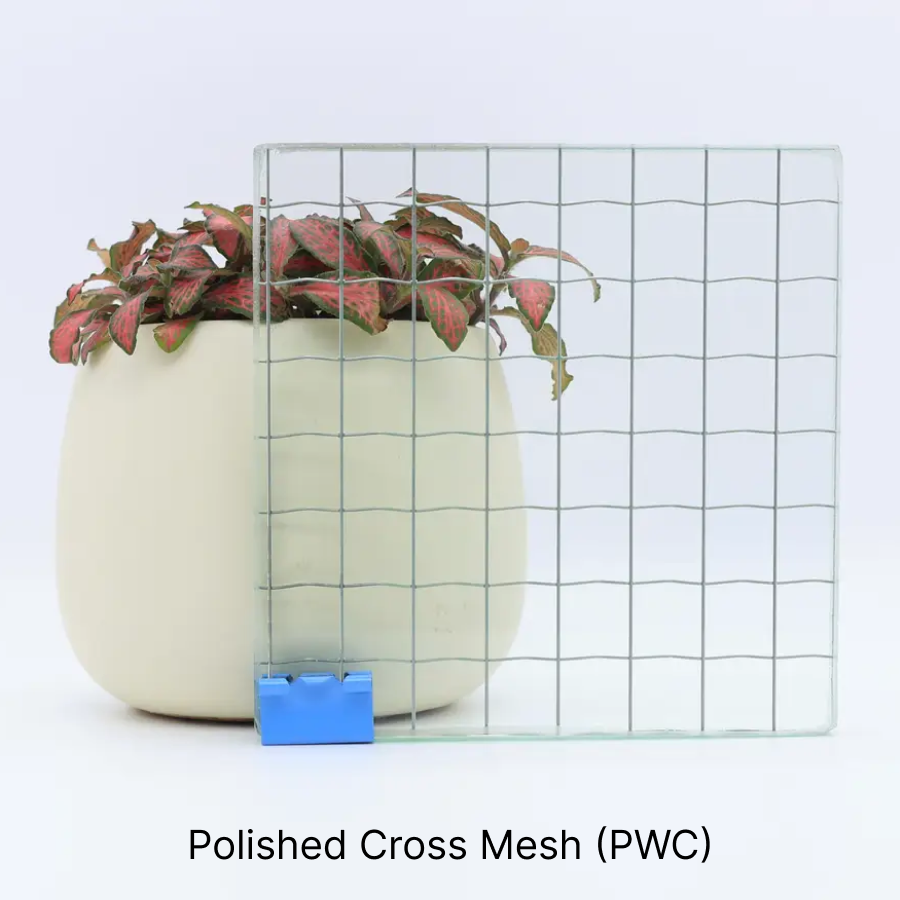

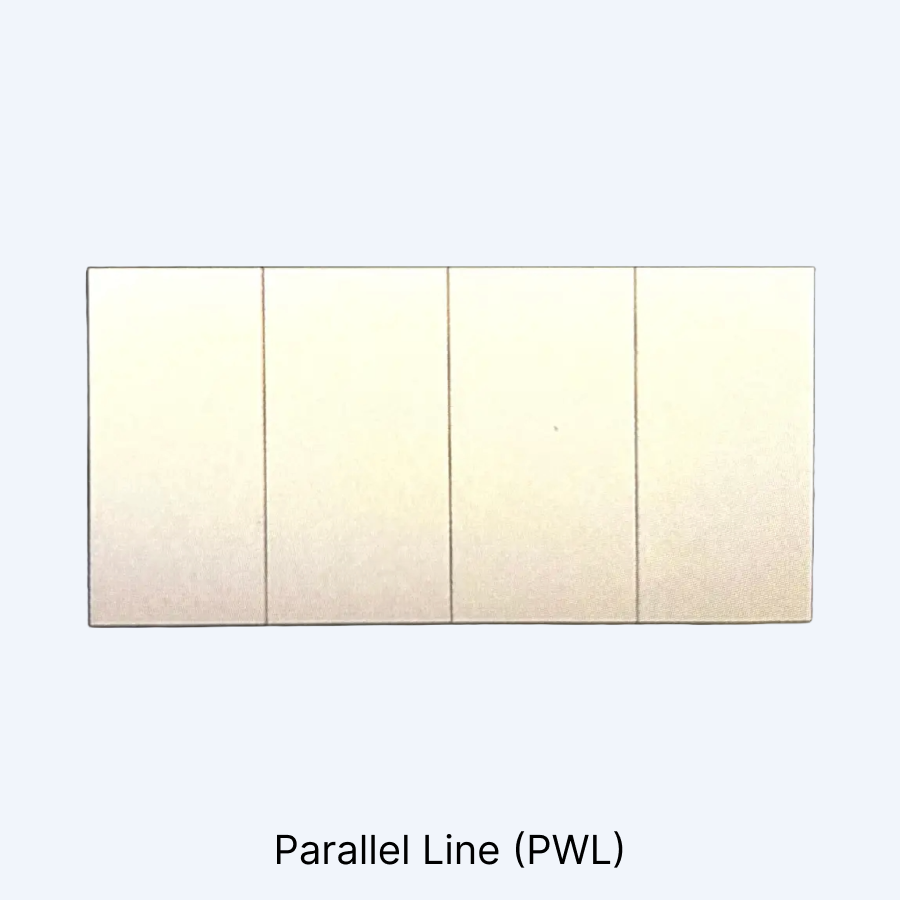

The wire is available in three types: diamond mesh, cross mesh, and straight parallel lines.

Contact Us

-

Fire resistance

-

The glass is formulated for fire protection performance. In case of fire, the glass cracks but broken

pieces tend to remain in the sashes rather than fall out, restricting the spread of flame and smoke.

*Except Polished Parallel Line -

Fallout resistance

- When the glass is broken by the impact, fragments tend to remain in the sashes rather than fall out. The chance of shattering is therefore less than that of float glass.

-

Crash prevention

- Wires embedded in glass will help to show appearance of glass compared to ordinary float glass, thus prevent from crashing into the glass.

Polished Wired Glass

Wired glass is produced by carefully embedding wire mesh or metal wires into glass. The wire is available in three types: diamond mesh, cross mesh, and straight parallel lines.

- Applications

-

- Exteriors and interiors of general constructions

- Doors and windows of buildings where fire protection is required

- Locations where fallout protection is required

- Locations where shatterproof is required

- Shop window

- Smoke barrier (Polished Parallel Line)

Wired Glass for Interior

This wired glass is produced by carefully embedding diamond wire mesh into glass. Even if the glass breaks, the wire will hold it in place. This is 5.2mm thick, considerably thinner than conventional wired glass (usually 6.8mm or 10mm).

Application: Interiors of houses and commercial facilities such as restaurants and shops as windows, doors, and furniture.

- Type

- Diamond Mesh

- Product Code

- PWH5.2

- Standard Thickness (mm)

- 5.2

- Size (inch)

- 96" x 72"

130" x 84"

Safety Precautions

The building designer is responsible for incorporating specific

characteristics of wired glass when determining the applicable locations and area for the glass.

Follow

the precautions stated in this catalog:

- The primary feature of polished wired glass (diamond mesh and cross mesh) is its fire resistance. These glass products are not safety glazing materials, and should not be used as such or in locations where human impact is possible or where safety glazing is required. However, there are some use of polished wired glass (diamond mesh and cross mesh) if building regulations require or permit it for such application.

- The manufacturer of the laminated glass using polished wired glass is responsible for certifying the fire protection performance in connection with the glazing method.

- To prevent accidental falls, do not step on the glass unit when installed in a skylight.

- When tested under fire test conditions, the performance of polished wired glass varies depending on the glass size and glazing method. For the details of testing conditions, refer to Underwriters Laboratories Inc./UL9.

Design and Installation Precautions

- When the wired glass is cut, the exposed metal wires are bent and hairline cracks can occur along the edges, decreasing strength.

- Exposed metal wires along the edges of the glass can be rusted by rainwater or condensation. Wired glass can be damaged as rust spreads.

- Maintain an ample distance between the surface of the glass and thick curtains, shades, lockers, etc.

- The glass surface should not be painted or coated with paper.

- The glass surface should not be exposed to direct currents of air from air-conditioning units.

- Calculate and carefully consider thermal values to avoid thermal cracking when a shading or decorative film is put on the glass surface.

- The maximum width of Parallel Line is 2,438mm. Where larger sizes are required, install crosswise.

Standards and Performance

- Central Glass Products' polished wired glass (diamond mesh and cross mesh) conforms to the fire performance test specified by the Japanese Industrial Standard (JIS R 3204) and the Building Code of Japan. They are also certified in the U.S.A., Canada, and Europe.

Certifications

-

JIS R3204

UL9,10B,10C

CUL9,10B,10C

EN 572